Smart MIni Portable Blue Tooth Thermal Label for Office Home Organization

Thermal Label

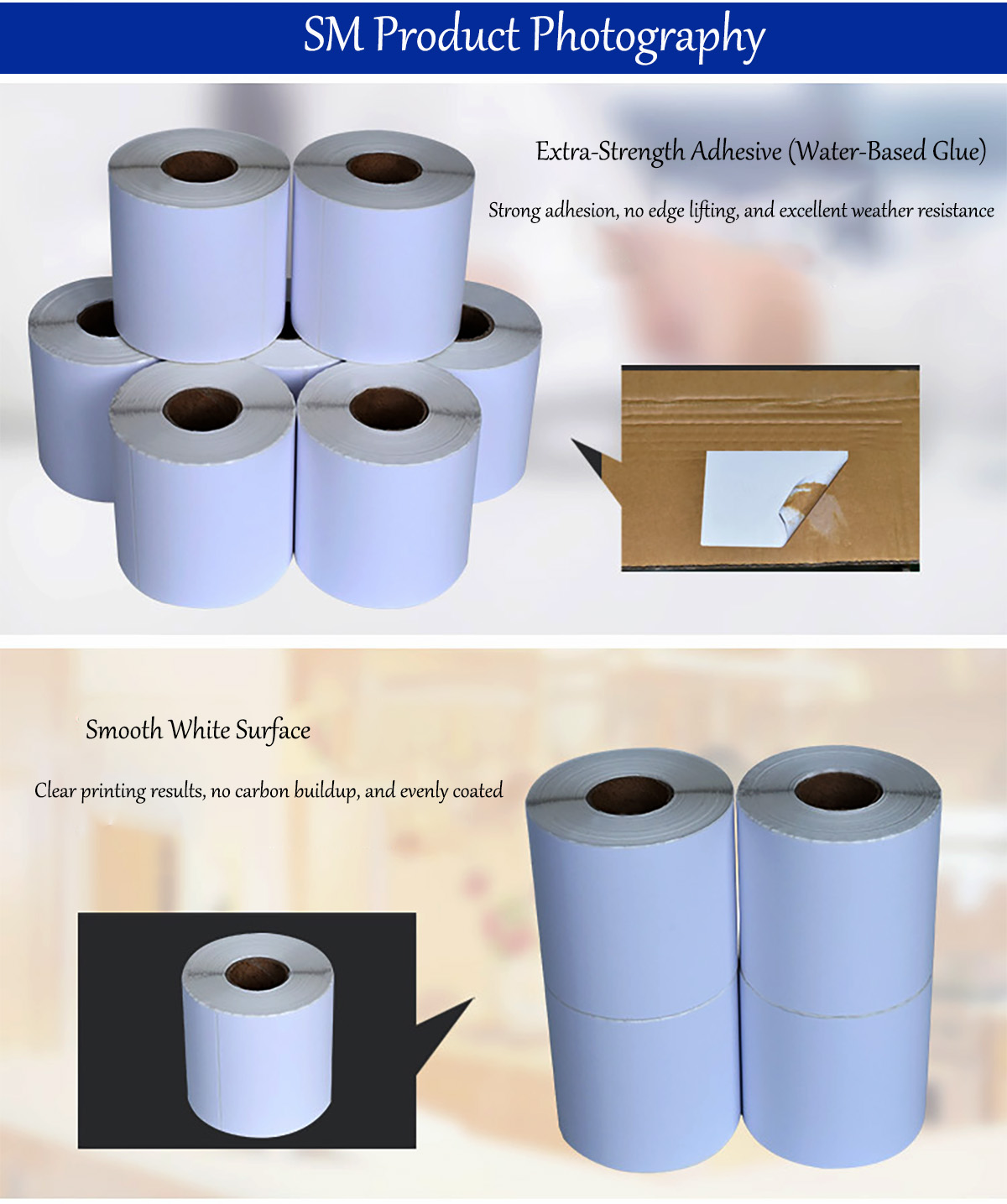

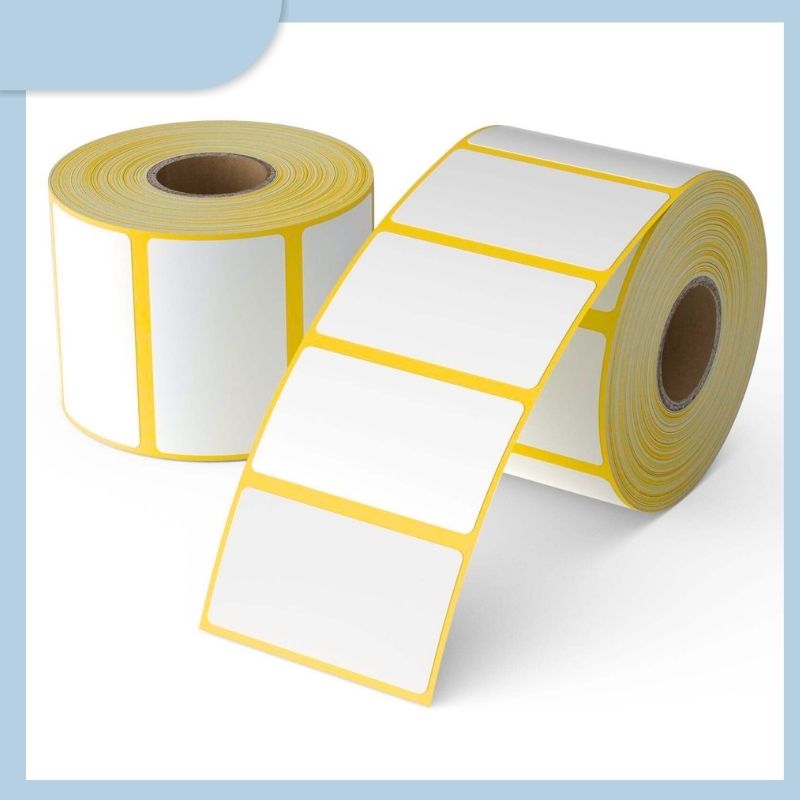

Thermal labels are specialized labels designed for thermal printing processes. They are widely used across various industries due to their efficiency, durability, and adaptability.

Characteristics

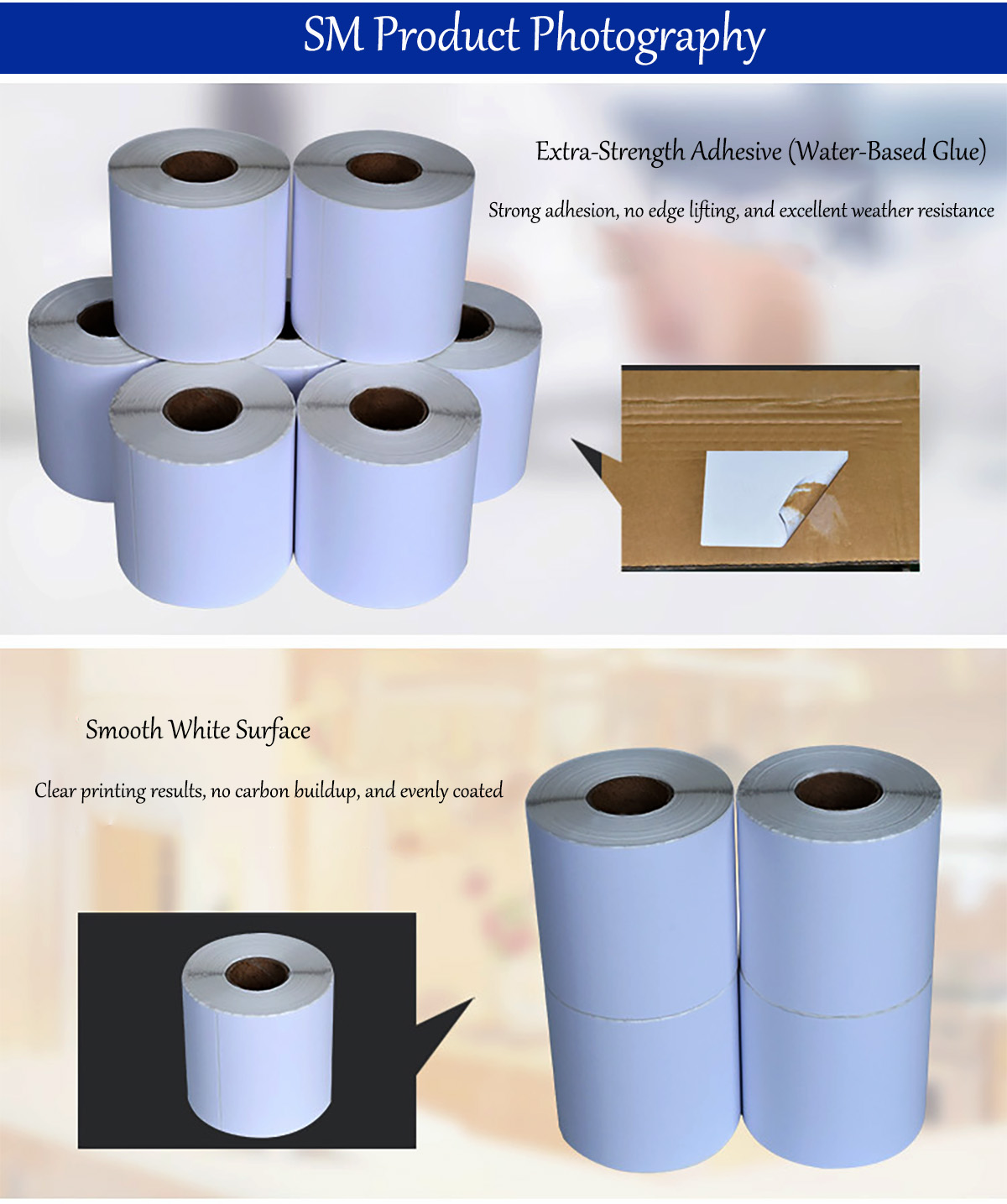

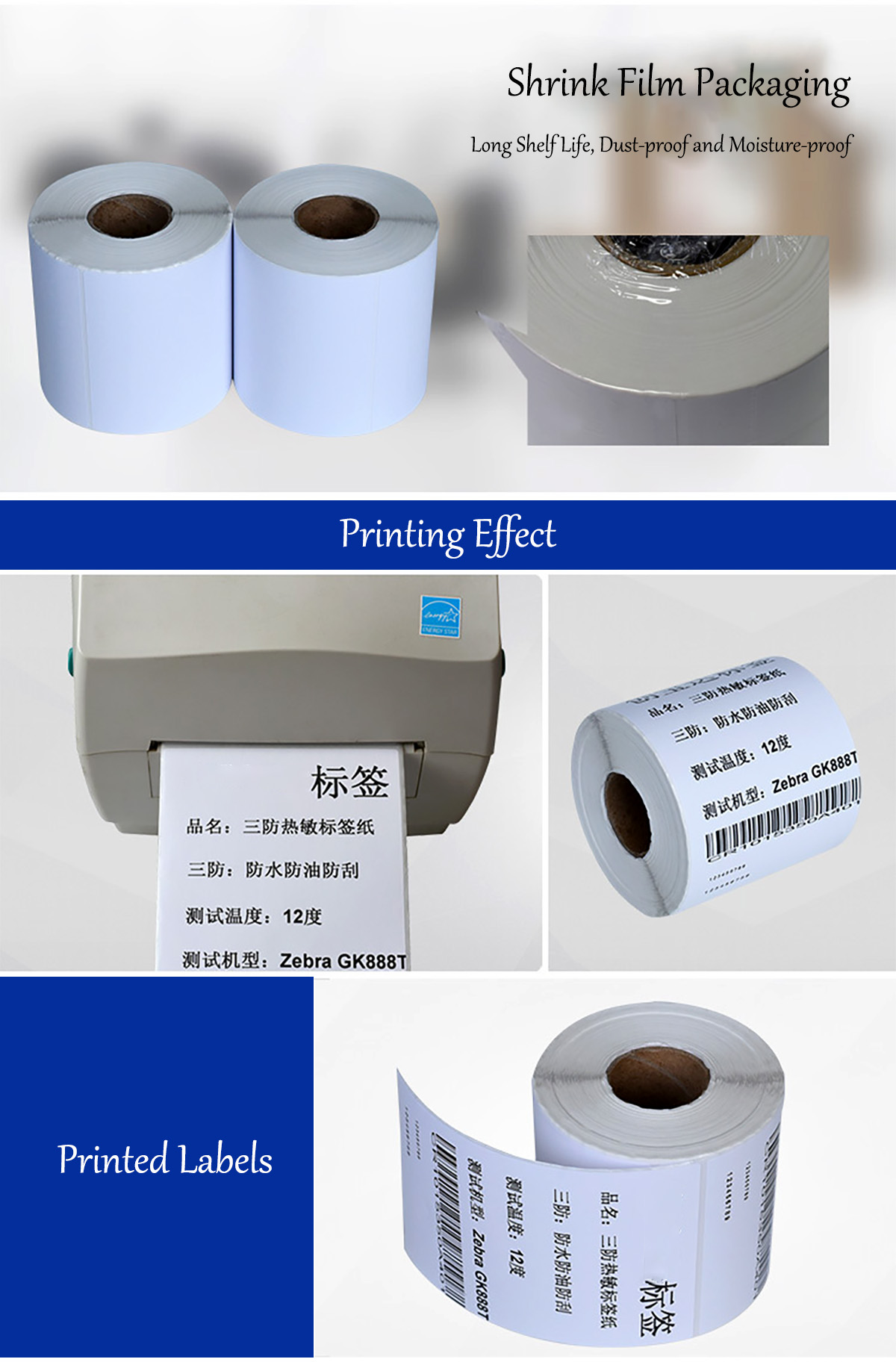

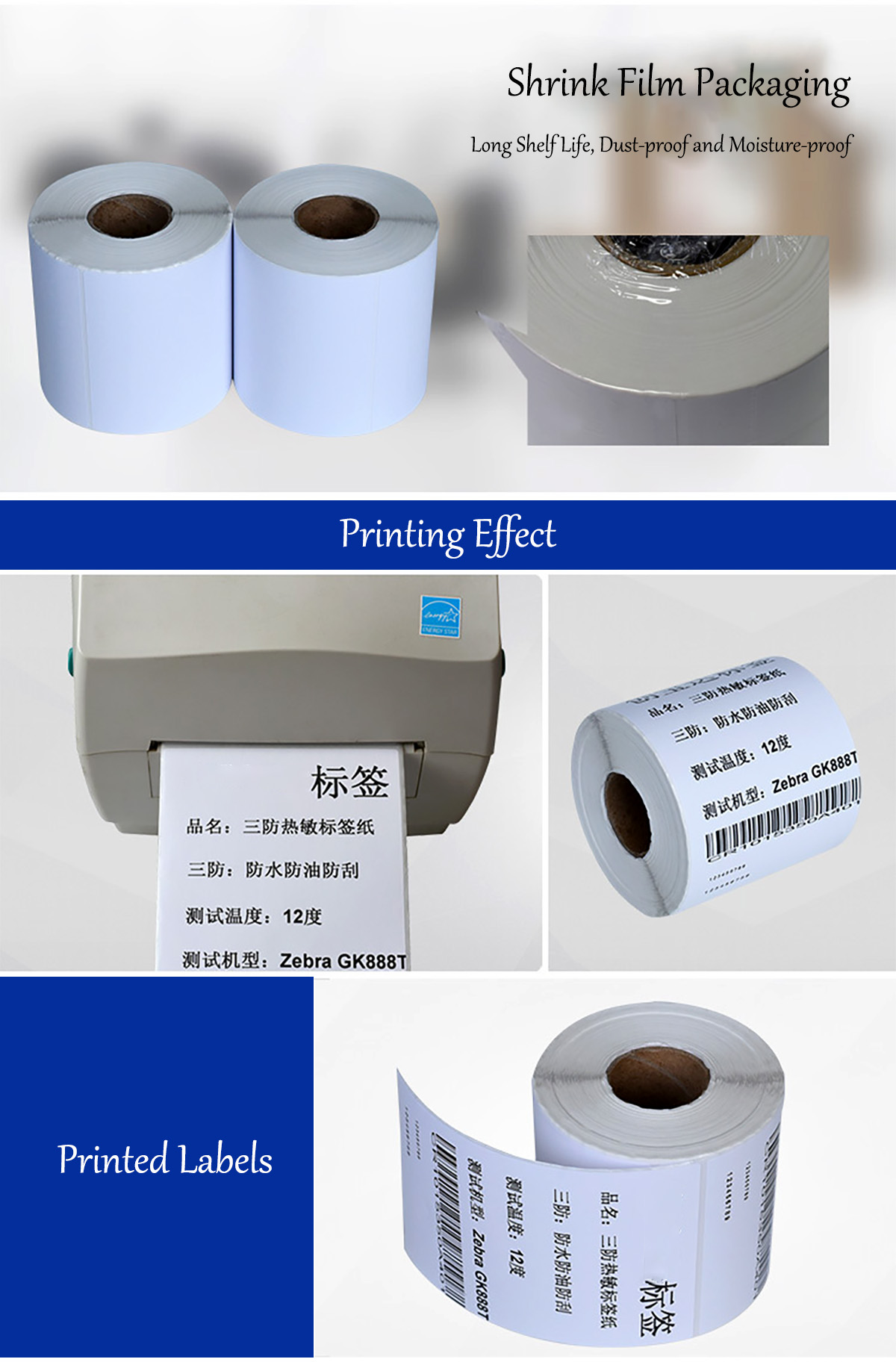

• High-Quality Printing: Thermal labels produce clear and detailed prints, making them ideal for applications requiring precise text and graphics.

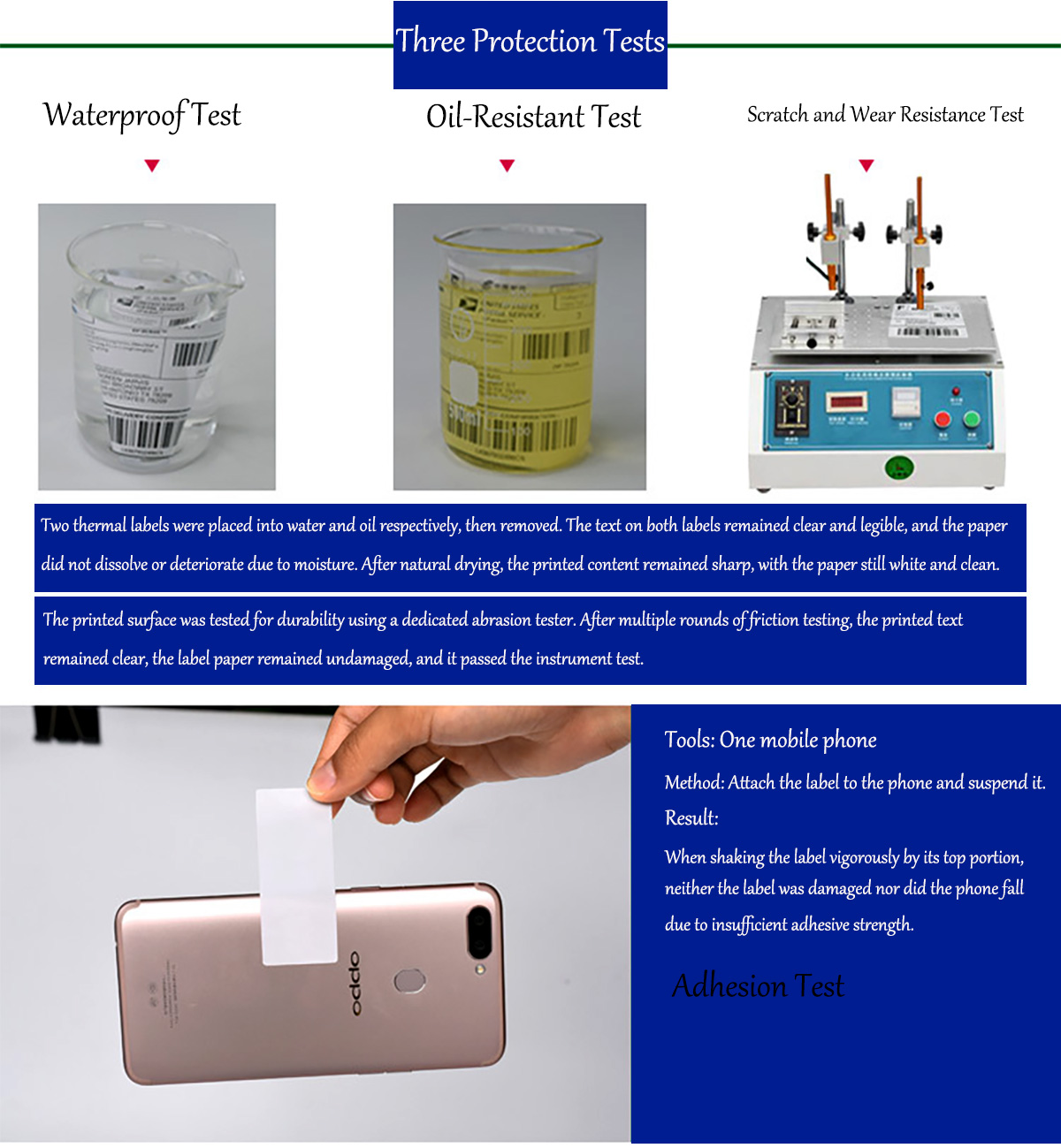

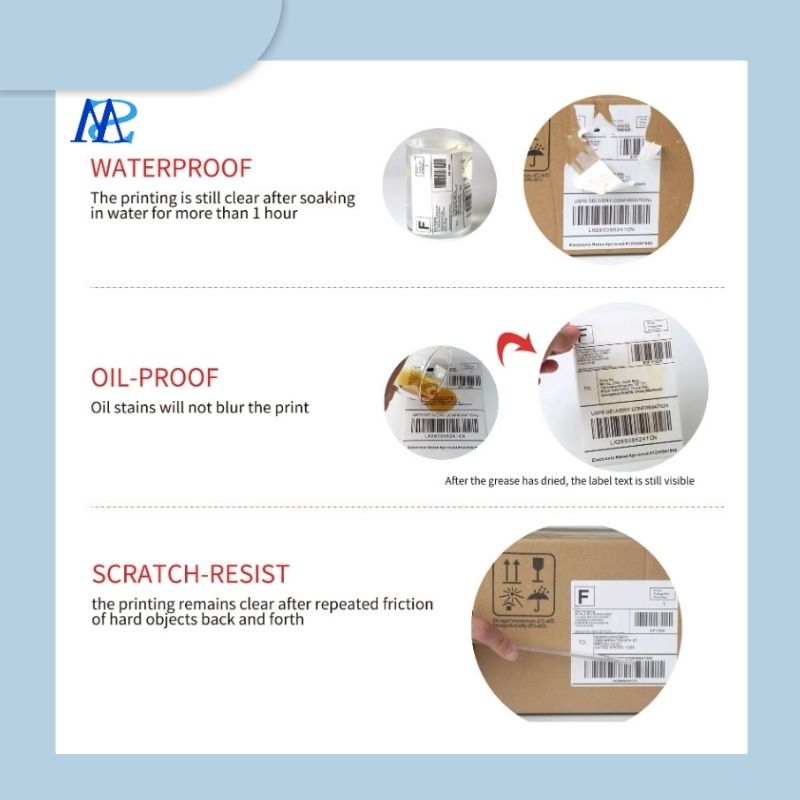

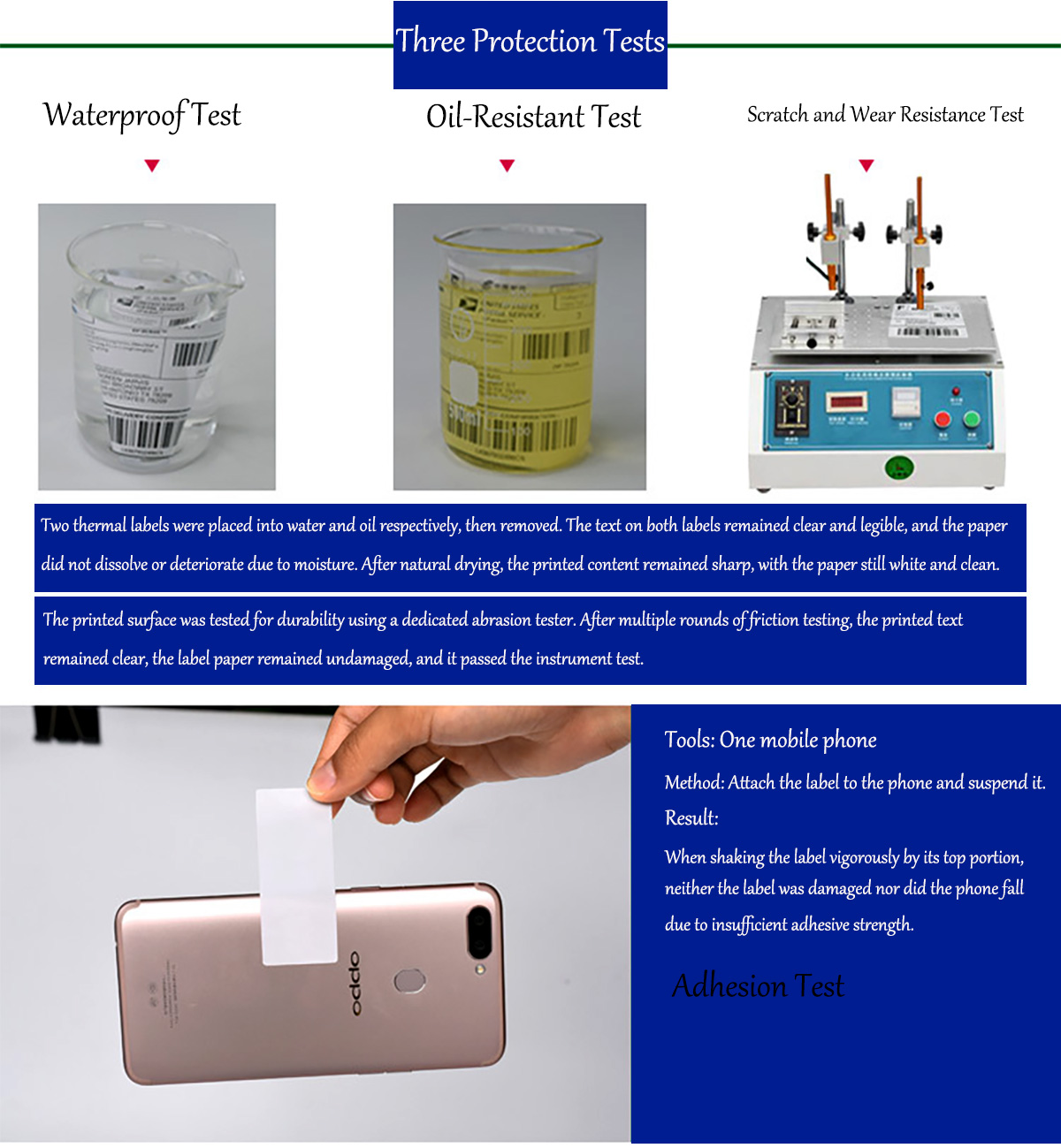

• Durability: They are resistant to wear, chemicals, and environmental factors, ensuring long-lasting legibility.

• Customizability: Thermal labels can be easily customized in terms of size, shape, and content, making them suitable for a wide range of applications.

• Efficiency: Thermal printing is a fast and efficient process, making it suitable for high-volume printing needs.

Types of Thermal Labels

1. Direct Thermal Labels: These labels use heat-sensitive paper that changes color when exposed to heat from the printer’s print head. They are ideal for applications where labels do not need to last for extended periods.

2. Thermal Transfer Labels: These labels require a ribbon that transfers ink onto the label material. They are more durable and suitable for applications where labels need to withstand harsh conditions.

Applications

• Logistics and Shipping: Used for package tracking, shipping labels, and inventory management.

• Retail: Ideal for price tags, product labels, and promotional materials.

• Healthcare: Used for patient identification, medical records, and equipment labeling.

• Manufacturing: Used for component identification, asset tracking, and quality control labels.

• Food and Beverage: Used for food labels, expiration dates, and ingredient information.

Printing Process

• Direct Thermal Printing: The printer applies heat directly to the label material, causing a chemical reaction that produces the printed image.

• Thermal Transfer Printing: The printer uses a ribbon to transfer ink onto the label material. The ribbon melts the ink onto the label, creating a durable and long-lasting print.

Storage and Handling

• Storage Conditions: Thermal labels should be stored in a cool, dry place away from direct sunlight and extreme temperatures.

• Handling: Care should be taken to avoid scratching or damaging the labels during handling and application.

Advantages

• Cost-Effective: Thermal labels are often more cost-effective than other types of labels, especially for high-volume printing.

• Quick Printing: Thermal printers can produce labels quickly, reducing downtime and increasing productivity.

• Versatility: Thermal labels can be used in a variety of applications and environments, making them a versatile choice for many businesses.

FAQ

Is it produced according to samples?

It can be produced according to samples or technical drawings based on MOQ

Payment terms:

T/T 100% deposit in advance

Delivery time:

It usually takes only 15-20 days after deposit

(depends on order specific and quantity )

Sample policy:

Free samples are available,shipping fees at clients’expense

FAQ Thermal Label |

Blurry or Faint Print |

Causes: • The printer temperature setting is too low. • The thermal print head is worn out. • Poor-quality labels are being used. • Dust or residue on the print head. Solutions: • Increase the printer's print density or temperature settings. • Clean the print head with an alcohol wipe. • Replace the worn print head. • Use high-quality thermal labels. |

Labels Turning Black Prematurely |

Causes: • Exposure to high temperatures, sunlight, or UV light. • Poor storage conditions (high temperature or humidity). • Chemicals or oil on the labels. Solutions: • Store labels in a cool, dry place, away from direct sunlight. • Keep labels in their original packaging until ready to use. • Avoid touching labels with greasy or dirty hands. |

Printer Fails to Recognize Labels |

Causes: • Incorrect printer settings for label size. • Sensors are not detecting the labels properly. • Labels are not correctly loaded into the printer. Solutions: • Check the printer settings to ensure they are set for 4x6-inch labels. • Clean the label sensors to remove dust or debris. • Reload the labels correctly to ensure smooth passage through the printer. |

Paper Jams with Labels |

Causes: • Labels are not properly aligned. • Printer rollers are dirty or sticky. • Damaged or defective label roll. Solutions: • Ensure labels are correctly loaded and aligned in the printer. • Clean the printer rollers with a lint-free cloth and alcohol. • Replace the current label roll if it is damaged or defective. |

Barcode Labels Not Scanning Properly |

Causes: • Low print density or resolution settings. • Labels are wrinkled or damaged. • Insufficient contrast between the barcode and background. Solutions: • Increase the print density settings to achieve clearer barcode printing. • Ensure labels are flat and wrinkle-free before printing. • Use higher resolution labels (e.g., 300 DPI for detailed barcodes). |

Printer Prints Blank Labels |

Causes: • Incorrect thermal labels are being used (not direct thermal). • Print head needs cleaning or replacement. • Incorrect printer settings. Solutions: • Ensure you are using direct thermal labels, not thermal transfer labels. • Clean the print head with an alcohol wipe. • Check printer settings to ensure print density and speed are optimized. |

Labels Lack Adhesion or Fall Off |

Causes: • Weak adhesive on the labels. • Surfaces are damp or dusty. • Labels are applied to rough or textured surfaces. Solutions: • Use high-quality labels with strong adhesive on the back. • Ensure surfaces are dry and clean before applying labels. • Press the labels firmly to ensure proper adhesion. |

Tel:

Tel:  Email:

Email: