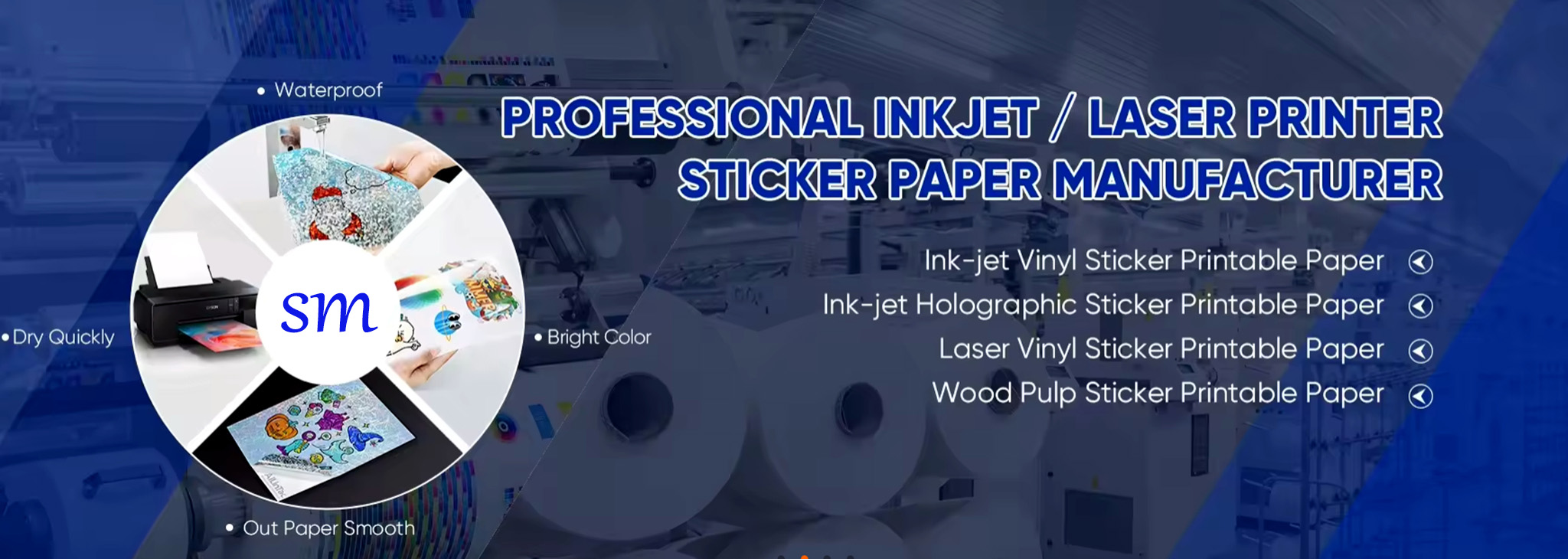

Injet & Laser Vinyl Sticker Printer Paper is a type of vinyl sticker paper designed for both inkjet and laser printers, with the following characteristics: Features • Material: Made from vinyl material, which offers good flexibility and durability, making it suitable for various sticker applications. • Compatibility: Suitable for both inkjet and laser printers, meeting different printing needs. • Surface Treatment: Typically available with either a glossy or matte coating. Glossy coatings are ideal for high-resolution printing, while matte coatings are suitable for applications that require anti-glare properties. Applications • Label Making: Ideal for creating product labels, packaging labels, and anti-counterfeiting labels. • Decorative Stickers: Can be used for decorating surfaces such as cars, computers, and mobile phones. • Advertising and Promotion: Suitable for making promotional stickers for advertising campaigns. Storage and Usage Suggestions

• Storage: Store in a dry, cool environment, avoiding direct sunlight and moisture.

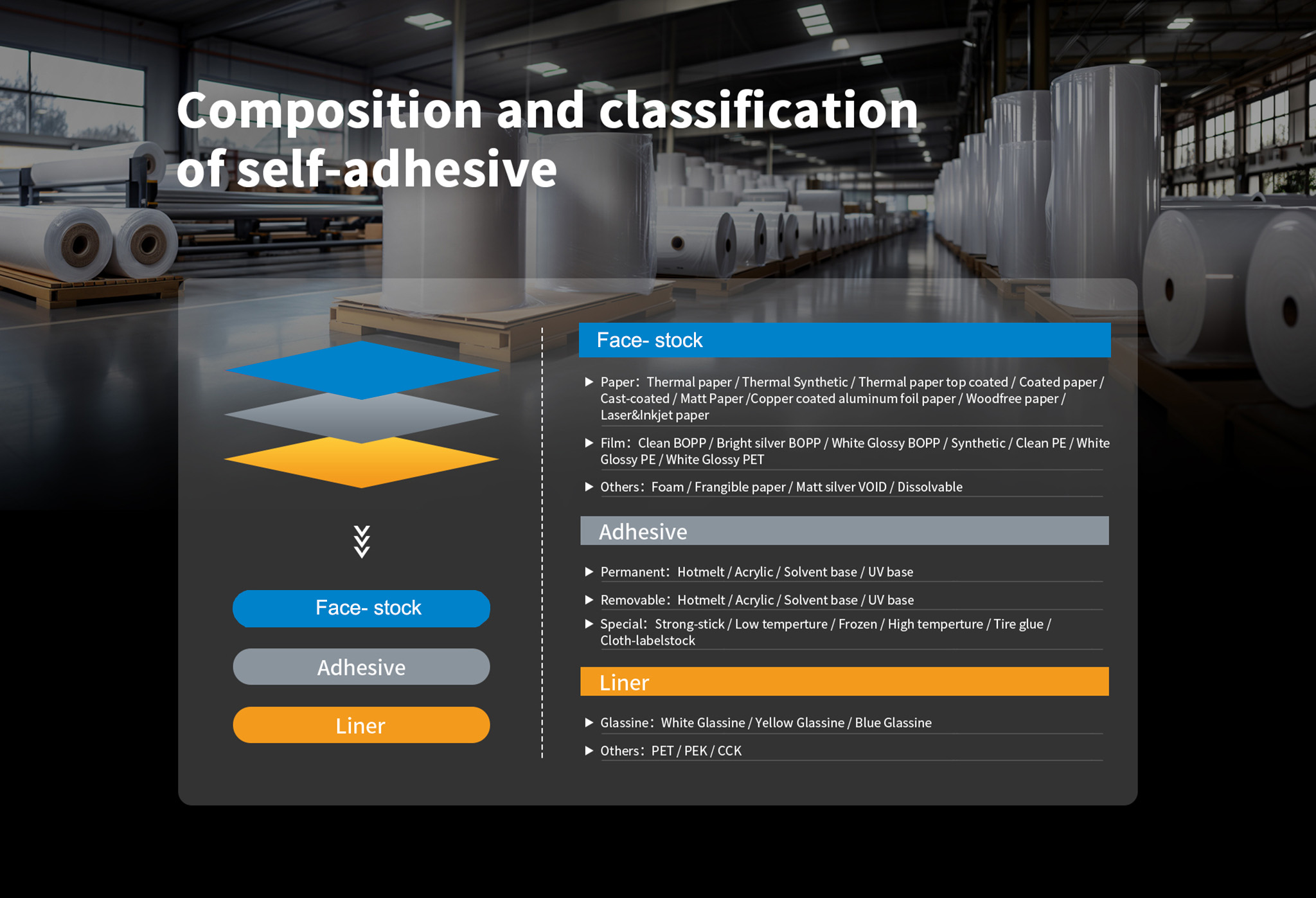

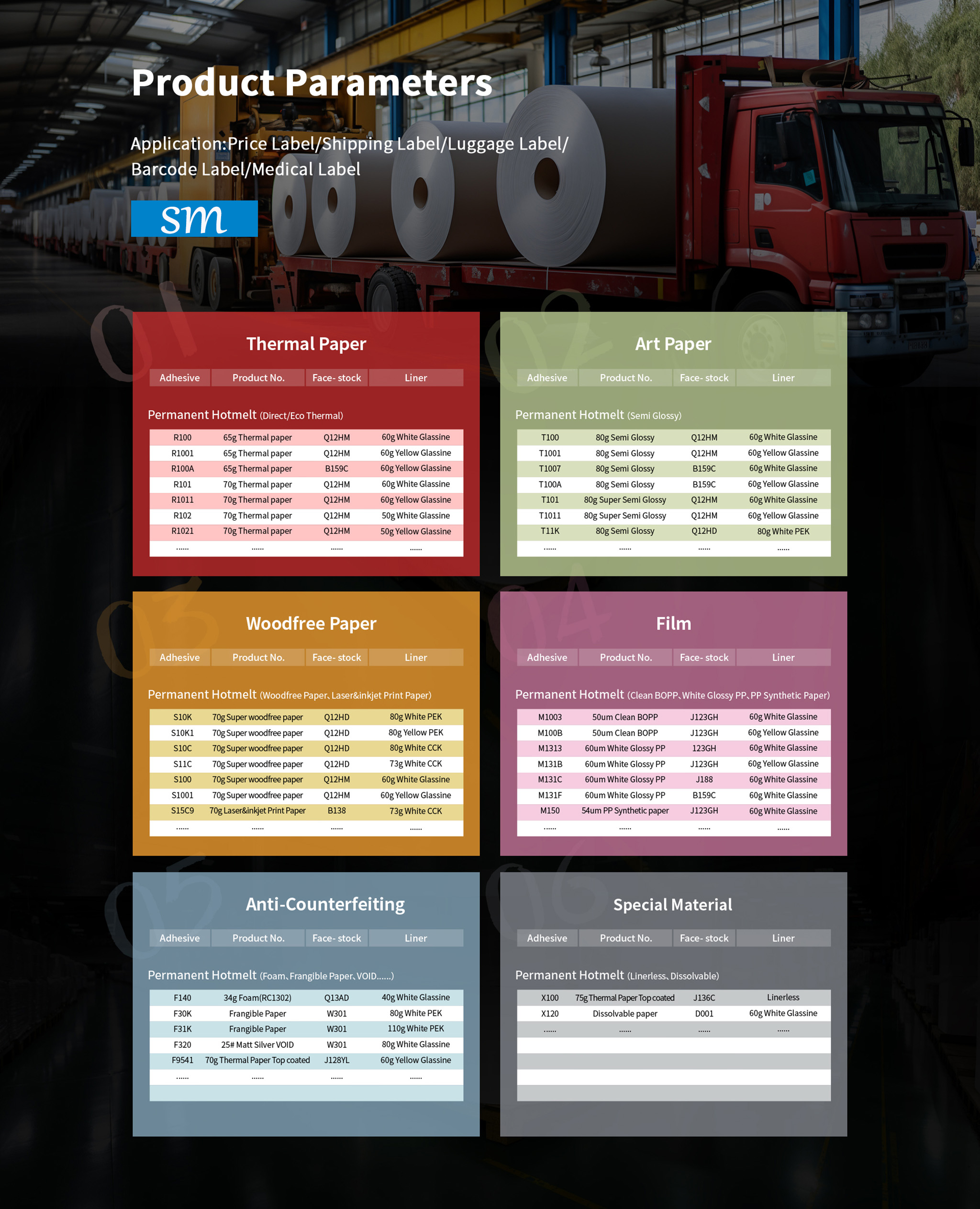

• Usage: Before application, clean the target surface to ensure it is dry and dust-free, which will enhance the adhesion of the stickers. | Label Material Jumbo Roll Specifications Label Material Jumbo Rolls are large-format rolls of label stock designed for high-volume printing applications. They are available in various materials and specifications to meet different industry needs. Key features include: • Material Options: Available in thermal paper, self-adhesive paper, synthetic materials like BOPP, PVC, PET, and more. • Customizable Sizes: Jumbo rolls can be tailored in terms of width (e.g., 1080mm, 1525mm) and length (e.g., 6000m) to match specific printing equipment requirements. • Adhesive Types: Offer a range of adhesive options, from removable to permanent, suitable for different surfaces like cardboard, plastic, and metal. • Coating Options: Some materials come with coatings such as silicone for specific applications like release paper. Applications Jumbo Roll Label Materials are widely used across multiple industries due to their versatility and durability: • Logistics and Shipping: Ideal for printing shipping labels, transport tags, and cargo identification to ensure clear and scannable information. • Retail and Supermarkets: Used for creating price tags, promotional labels, and product identification to help manage inventory efficiently. • Manufacturing and Warehousing: Effective for inventory labels, shelf tags, and asset identification to enhance warehouse management. • Healthcare: Suitable for labeling medications, laboratory samples, and patient identification. • Food and Pharmaceutical Industries: Used for food packaging labels and batch information to ensure compliance and accuracy. |

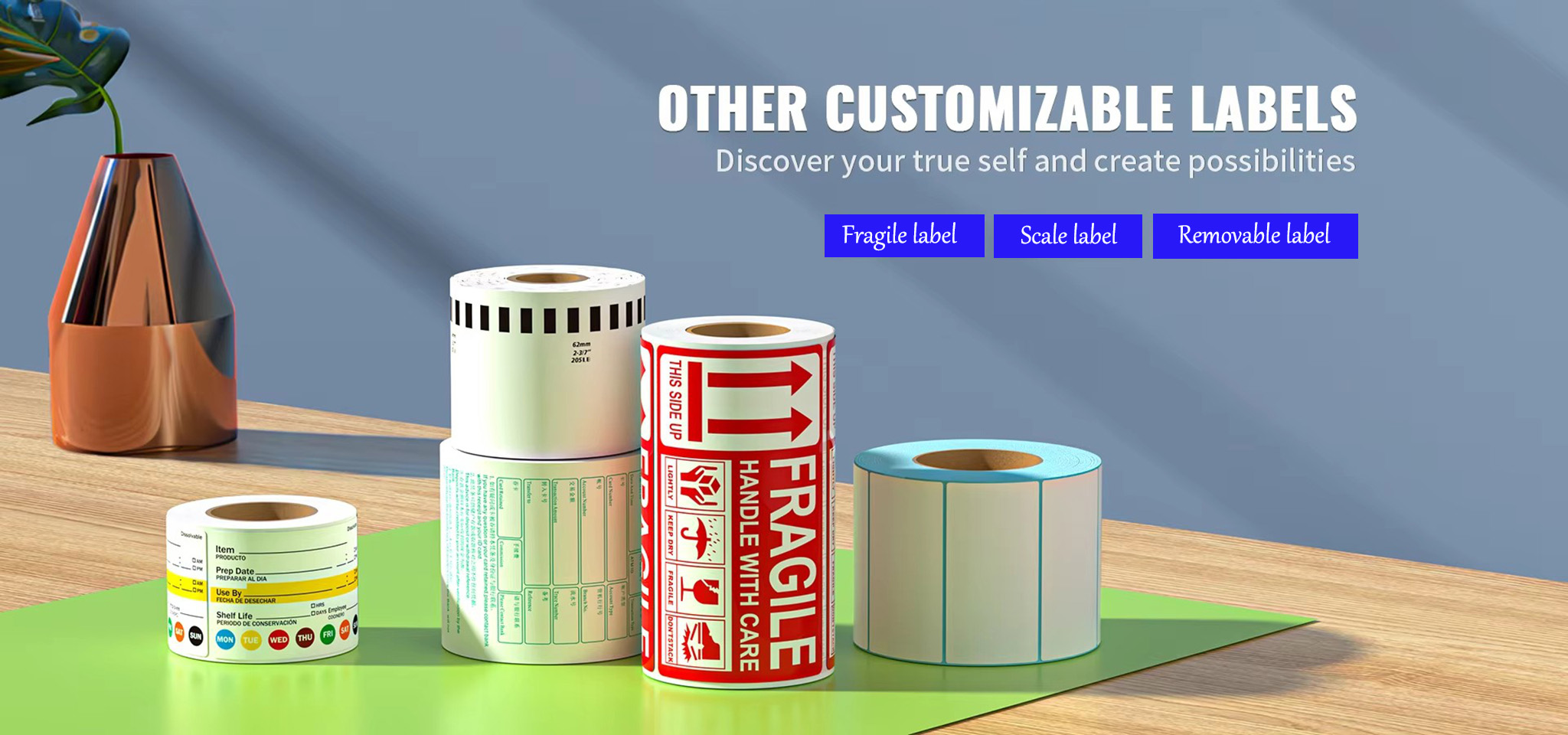

Material Options 1. Aggressive White Matte • Description: Bright-white paper-based material with strong adhesive, ideal for hard-to-stick surfaces like corrugated boxes. Suitable for extreme temperatures but not weatherproof. • Use Case: Best for durable, non-weatherproof applications. 2. Standard White Matte and Recycled White Matte • Description: Affordable paper-based options with a clean, professional look. Not weatherproof. • Use Case: Suitable for standard shipping needs in controlled environments. 3. Weatherproof Matte Inkjet and Weatherproof Polyester Laser • Description: Durable labels that maintain excellent scannability in various weather conditions. • Use Case: Ideal for packages exposed to harsh environments or requiring reliable tracking. 4. Direct Thermal Labels • Description: Cost-effective, designed for thermal printing without ink or toner. Suitable for frequent shippers. • Use Case: On-demand shipping applications. 5. Thermal Transfer Labels • Description: Similar to Direct Thermal labels but require a ribbon for printing. More durable and customizable. • Use Case: Suitable for challenging conditions with design flexibility. 6. Polypropylene Labels • Description: Glossy finish, resistant to moisture and suitable for curved surfaces. Lasts six months to a year outdoors. • Use Case: Package labels, drum labels, item tracking. 7. Clear Film Labels • Description: Provide a no-label look, perfect for transparent containers. Available in matte or glossy finishes. • Use Case: Enhances product visibility while providing necessary information. 8. Holographic Labels • Description: Waterproof and oil-resistant, with a rainbow sheen that changes with light and reflection. • Use Case: Ideal for high-visibility applications, though not recommended for postage. | Fragile Labels • Usage: These labels are used to mark packages containing fragile items, such as glassware, electronics, and ceramics. They remind handlers and transporters to handle the items with care. • Design Features: • Text: They typically feature prominent text such as “Fragile” or “Handle with Care”. • Symbols: They may include the international symbol for fragile items, which is universally understood even if the language is not. • Color: Bright colors like red or yellow are often used to attract attention. • Material: Common materials include waterproof polyester and semi-gloss paper, which are durable and resistant to moisture, tearing, and fading. Warning Labels • Usage: These labels are used to convey important safety information about the contents of a package, such as hazardous materials, flammable items, or toxic substances. • Design Features: • Text: They include clear warning statements, such as “Caution: Contains Hazardous Materials”. • Symbols: Specific icons are used, such as the skull and crossbones (indicating toxicity) or a flame (indicating flammability). • Color: Bright colors like red or yellow are typically used to highlight the warning. • Material: They need to be made from waterproof and chemical-resistant materials to ensure that the labels remain legible in various conditions. Application Scenarios • Logistics and Transportation: In industries such as courier services, moving, and warehousing, fragile and warning labels are widely used to reduce the risk of damage to items during transit. • Industrial Production: In laboratories and factories, they are used to mark sensitive equipment or hazardous chemicals. • Retail Packaging: They remind consumers to be cautious when purchasing and using products that are fragile. |

Advantages and Features 1. Fast Printing Speed: Thermal Paper Labels can be printed at extremely high speeds, allowing for the rapid production of large quantities of labels in a short period of time. This significantly improves work efficiency and is particularly suitable for industries such as logistics, retail, and healthcare, where there is a high demand for quick label printing. 2. Clear and Durable Information: The text and patterns printed on thermal paper labels are highly clear and have good contrast, making them easily readable even in low-light conditions. Moreover, with the optimization of the thermosensitive coating formula and manufacturing processes, the storage life of modern thermal paper labels has been significantly extended, ensuring the integrity of the information over a certain period of time. 3. Easy Operation: Thermal paper label printers have a simple structure and are easy to operate. Users simply need to load the thermal paper labels into the printer and make a few basic settings to start printing. There is no need to worry about issues such as ink clogging nozzles or ribbon breakage, which greatly reduces equipment maintenance time and costs. 4. Environmentally Friendly and Pollution-Free: Since thermal paper label printing does not use ink, ribbons, or other consumables, it generates no chemical pollution or waste. This aligns with modern society's requirements for environmental protection. Application Scenarios 1. Logistics and Courier Services: In the logistics industry, thermal paper labels are widely used for package identification. Couriers can quickly print labels on-site that include recipient information, package weight, destination, and other details, and then affix them to the packages to ensure accurate and rapid delivery to the recipients. 2. Retail Industry: In supermarkets, convenience stores, and other retail settings, thermal paper labels can be used for product price tags and promotional information labels. Merchants can quickly print and update labels based on real-time product prices and promotional activities, providing customers with accurate shopping information. 3. Healthcare Field: Thermal paper labels also play an important role in the healthcare industry. For example, in hospital pharmacies, they can be used to print drug labels that specify the name, dosage, and expiration date of the medication; in the laboratory, they can be used for sample labels to record key information such as patient names and test items, ensuring the accuracy and safety of the medical process. 4. Industrial Manufacturing: In industrial production, thermal paper labels can be used for product identification, component labels, and production process labels. By attaching thermal paper labels to products or components, it is easy to record information such as the production date, batch number, and quality inspection details, facilitating product traceability and management. | Properties of Reflective Film • High Reflectivity: Reflective films are engineered to reflect a significant amount of light that hits their surface. This is achieved through the use of specialized materials and coatings. • Durability: Many reflective films are designed to be weather-resistant, UV-resistant, and resistant to wear and tear. This makes them suitable for outdoor use. • Visibility: Reflective films are highly visible, especially at night or in low-light conditions. They can reflect light from headlights, streetlights, or other sources, making them ideal for safety applications. Types of Reflective Film 1. Engineered Retroreflective Films: • Prismatic Reflective Films: These films use micro-prisms to reflect light directly back to its source. They are highly efficient and are commonly used in traffic signs and safety vests. • Glass Bead Reflective Films: These films use tiny glass beads to scatter and reflect light. They are less efficient than prismatic films but are still widely used for their cost-effectiveness. 2. Non-Retroreflective Films: • Mirror-like Reflective Films: These films reflect light in a more diffuse manner, similar to a mirror. They are often used for decorative purposes or in applications where a wide-angle reflection is needed. Applications of Reflective Film 1. Traffic and Road Safety: • Traffic Signs: Reflective films are used to make road signs more visible at night, improving driver safety. • Road Markings: Reflective tape is often applied to road surfaces to enhance the visibility of lane markings and other important indicators. • Vehicle Reflectors: Reflective films are used on vehicles, including cars, trucks, and emergency vehicles, to make them more visible to other drivers. 2. Personal Safety: • Safety Vests and Clothing: Reflective films are used to create high-visibility vests and clothing for workers in construction, road maintenance, and other industries where visibility is crucial. • Bicycle and Motorcycle Safety: Reflective films are applied to helmets, jackets, and other gear to make cyclists and motorcyclists more visible to drivers. 3. Decorative and Architectural Uses: • Signage: Reflective films are used to create eye-catching signs for businesses, events, and public spaces. • Architectural Elements: Reflective films can be applied to building facades, windows, and other architectural elements to enhance their appearance and provide a unique visual effect. 4. Industrial and Commercial Applications: • Warehouse and Logistics: Reflective films are used to mark storage areas, aisles, and equipment to improve visibility and safety within warehouses. • Security and Surveillance: Reflective films can be used to enhance the visibility of security cameras and other surveillance equipment. |

Tel:

Tel:  Email:

Email: